The modular display options facing SME engineers can seem somewhat daunting, but in simple terms there are three approaches: the first approach is to choose a display module with a simple three-wire connection and a Smart Plug & Play interface to allow the user to define the graphic layout of the touch screen. This makes the set-up easy and very fast, ensuring a rapid time-to-market. The three-wire connection also makes it very simple for engineers to upgrade character-based legacy products with a modern touch display.

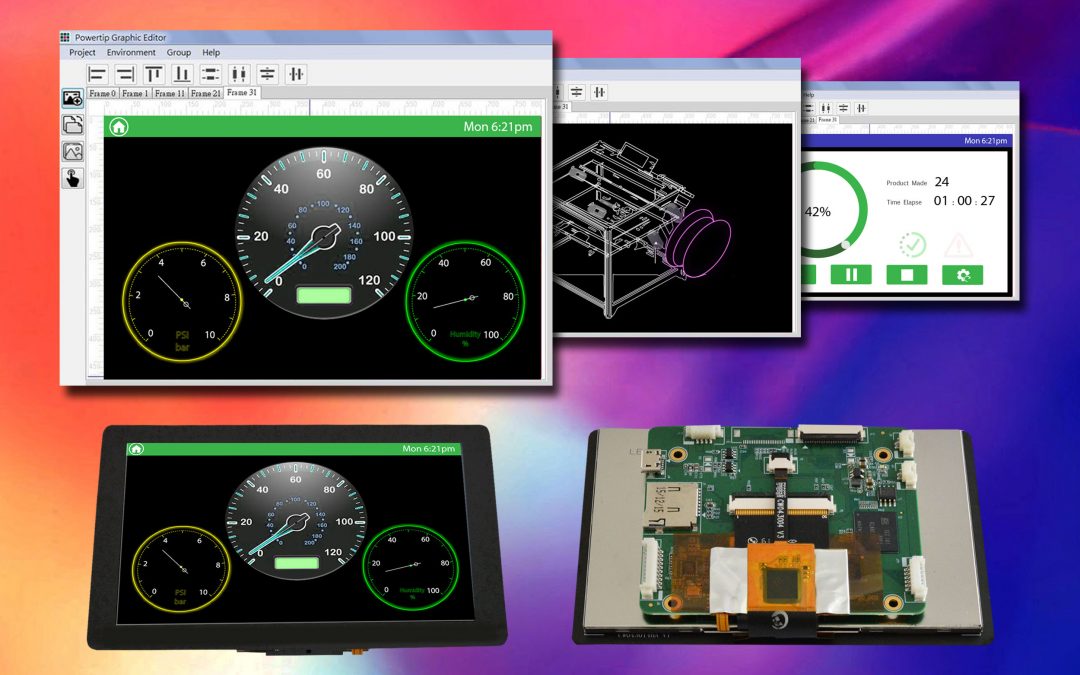

The second option is to select a module with a more powerful processor, aimed at applications where rapid response times and smooth graphics are needed. Time-to-market will still be of essence to the SME, so an easy-to-use Plug & Play graphic layout design interface will still be of benefit. Ideally Board Support software will allow customers to rapidly develop code.

The third approach is for applications demanding the highest of processor performance, providing extremely rapid response times and the ultimate in smooth 2D/3D graphics, full HD Multi-media playback/streaming capability. Development engineers will typically want to program their own custom display graphics, in this instance Linux-based software tools are commonly used.

Choosing the most appropriate approach

Inelco Hunter, in partnership with Powertip, have solutions to all three touch screen approaches.

At the simplest level, Inelco Hunter offers the Powertip Smart UART family of three-wire Smart touch screens which range from 3” to 10”. They all feature Plug & Play GUI Editor software to define the display’s graphic touch interface. A wide choice of graphic buttons are provided as standard, with the option of creating custom buttons and graphics very quickly. Despite the relative simplicity, the screens provide high resolution and wide viewing angles – typically 800×480 pixels with a Full View (FVA) 80°+ viewing angle.

Where more power is needed

The next-level modular system solution that Inelco Hunter offers is for the more demanding applications. The Powertip MCU range of touch display modules incorporates a powerful STMicroelectronics MCU with an Arm Cortex-M7 480MHz core running at 480Mhz. The MCU provides a very high level of performance, resulting in rapid response times and very smooth graphics.

For example, instrumentation products will be able plot graphs quickly and without jitter and support full MJPEG video playback.

Time-to-market is of essence and the easy-to-use TouchGFX Plug & Play software will enable developers to define the display’s graphic touch interface very quickly using graphic icons from the supplied library stock. In addition, custom graphic blocks can be quickly generated or Graphics can be uploaded from external sources direct to the system.

Uniquely, Inelco Hunter provide their own BSP (Board Support Package) allowing customers to develop using STM32CubeIDE or KEIL MDK, effectively turning the display into a standalone embedded module in its own right. Screen sizes range from 3.5” to 5” with a high resolution and wide viewing angles – typically 480×272 pixels with an 80°+ full viewing angle and a brightness of 800+ lumens.

Where the ultimate in power is needed

The Inelco Powertip MPU range of displays utilises an NXP or Rockchip Quad core 64-bit ARM Cortex-A53/A35 running at 1.6GHz MPU. These processors provide what might be called blindingly fast response times and the ultimate in smooth 2D/3D graphics plus Full HD multi-media playback/streaming capability. Screen sizes range from 5” to 10”.

Engineers will often want to work with Linux-based software to develop their own graphic interfaces. The MPU range supports popular Linux-based OS like Debian, Ubuntu, Buildroot and Yocto and comes with connectivity such as UART, SPI, MIPI-CSI/DSI, I2S and SDIO built in. Inelco Hunter offers local UK Engineering support and customised solutions, including casing options and custom-OS software for example.

Inelco Hunter engineers will work with the SME engineers to develop custom software at the customer’s request. This is believed to be a unique proposition which no other Powertip distributor offers.

Support is Key

Inelco Hunter provides helpful, in-depth engineering support, ensuring rapid implementation, speeding up the customer’s time-to-market. This added-value support is at the core of Inelco’s philosophy, and has been for the last 30 years, setting them apart from the “stock & ship” distributors.

Customers are increasingly looking for complete solutions with a high degree of service, to provide them with truly converged, totally embedded solutions. This has inspired Inelco Hunter to develop their “Totally Embedded” range of services and embedded hardware/software solutions which include: Camera Modules, SoM Modules, Smart Display Modules, Embedded Systems (Pi plus Displays), Thermal Printers, Connectors and Cable Harnesses.