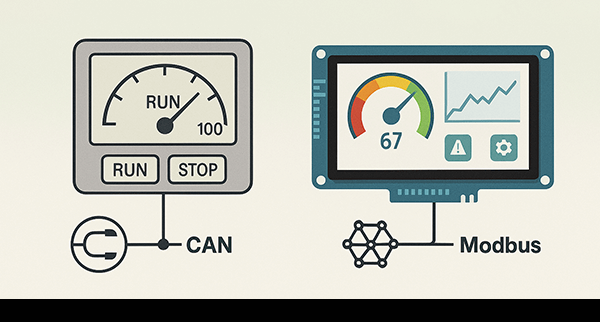

In industrial automation, vehicle systems, and smart energy devices, CAN and Modbus protocols are widely used for communication between controllers, sensors, and user interface displays. These displays often rely on third-party, proprietary HMI modules that act as passive endpoints, rendering values received over CAN bus or Modbus RTU/TCP.

While widely adopted, these typical HMI displays come with trade-offs: limited customisation, outdated graphics, high cost, and closed firmware. Today, powerful ready-made STM32 display solutions offer an affordable, flexible and modern alternative – capable of directly handling both CAN and Modbus protocols while delivering rich, interactive GUIs.

This article looks at how (and why) to replace traditional CAN/Modbus displays with STM32-based display platforms, and how developers can streamline development using ST’s ecosystem.

The problem with traditional CAN/Modbus Displays

Common features of traditional CAN/Modbus displays:

- Basic LCD/TFT display with limited resolution

- Serial interface (CAN or RS-485)

- Predefined GUI screens (fixed layout)

- Firmware closed to the developer/supplier

- Proprietary configuration tools or scripting

Challenges:

- Minimal UI flexibility

- Hard to scale or customise

- Firmware bug fix/upgrade highly depends on the developer/supplier

- Limited/No animations, touch interaction, or real-time responsiveness

Why use ready-made STM32 Display Solutions?

STM32 displays from Inelco Hunter power a wide range of HMI-ready kits with built-in display, touch interfaces and free BSP. These boards can directly handle both CAN (via Classic/FDCAN) and Modbus RTU/TCP (via UART or Ethernet), removing the need for a separate HMI module.

Core Benefits

Full Protocol Support (CAN & Modbus)

- Use FDCAN peripheral to receive/send CAN messages

- Use UART or Ethernet to communicate over Modbus RTU/TCP

- Implement custom protocol handlers, message parsing, and control logic

Rich, interactive GUI

- Build modern interfaces using TouchGFX, a free graphics framework

- Add animated gauges, charts, warning messages, and multilingual UIs

- Customise layout and UI behaviour down to the pixel

Integrated logic and UI

- Replace the split architecture (controller + HMI) with a single STM32 board

- UI, logic, data parsing, and even logging handled on one device

Field Upgradable & Scalable

- Add SD card or Ethernet for future firmware updates

- Easily switch between UART/RS232/RS485, CAN, or Ethernet protocols

- Port GUI projects across STM32 series with minimal code change

Cost-Effective

- Reduce BOM: one MCU, one display, fewer external components

- No license fees for graphics tools or runtime software

Replacing a typical CAN/Modbus Display: step by step

Step 1: Select a suitable ready-made STM32 Display from Inelco Hunter

Choose based on:

- Screen size & touch requirements

- Numbers of GPIO or interface (e.g. UART, CAN or Ethernet)

- Cover lens requirements

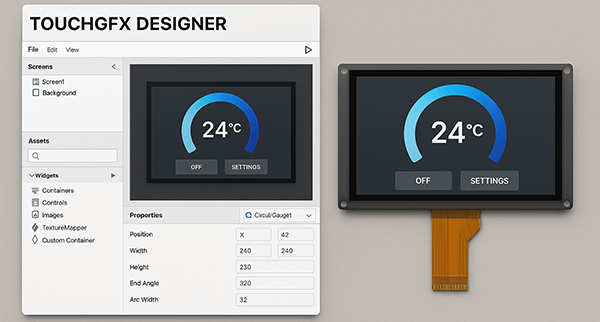

Step 2: Design GUI using TouchGFX

- Use TouchGFX Designer to create a graphical user interface

- Add widgets for indicators, input fields, graphs, or alarms

- Bind data points to variables representing CAN/Modbus registers

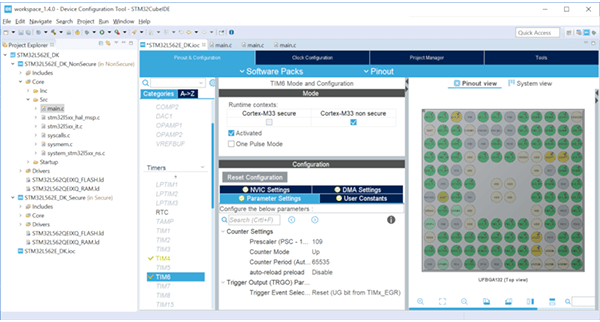

Step 3: Implement CAN/Modbus Protocol Stack

- For CAN: configure FDCAN in STM32CubeMX and handle message IDs

- For Modbus:

RTU: Use UART + software stack (e.g., Modbus RTU slave implementation) - TCP: Use Ethernet + lightweight IP stack (LwIP) and Modbus TCP layer

- For Modbus:

- Parse incoming data and update GUI in real time

Step 4: Test and validate

- Connect to a real or simulated CAN/Modbus master

- Ensure messages are received and GUI reflects real-time updates

- Handle edge cases: communication loss, checksum errors, out-of-range values

Step 5: Optimise and deploy

- Add watchdog timers, UI timeouts, and fault detection

- Use DMA for efficient data handling and screen refresh

- Deploy with support for future updates via SD card, USB, or network

Use Case: From Legacy Modbus Display to STM32 HMI

Legacy setup: An RS-485 Modbus RTU display receives 10 registers from a PLC and shows sensor values and alarms on a 128×64 monochrome screen.

Modern STM32 solution:

- Select 5” JXMA800580T030-ZHC with 800×480 color display and capacitive touch

- GUI designed in TouchGFX showing real-time trends, icons, and animated gauges

- RS-485 via UART and on-board driver to handles Modbus RTU communication

- UI includes alarm popups, multi-page navigation, and configuration menu

Result: A modern user experience, improved maintainability, and no recurring software costs.

Conclusion

Ready-made STM32 display solutions present a powerful alternative to traditional CAN and Modbus HMI displays. By combining protocol support, rich GUIs, and embedded control in one platform, developers can create highly customised and scalable interfaces for industrial and embedded systems.

With the support of tools like TouchGFX and STM32CubeMX, moving from rigid legacy displays to dynamic STM32-based HMIs is easier and more cost-effective than ever.

Whether you are launching a new product or upgrading an existing design, Inelco Hunter’s STM32 displays provide the flexibility, performance, and time-to-market advantages that today’s embedded projects demand.

Ready to accelerate your next project?

Contact us today to learn more about how Inelco Hunter’s STM32 display solutions can help you deliver outstanding embedded experiences – faster and smarter.