Rugged printers are a vital component of many electronic devices and integrating them into the end-product can be a challenge in terms of sourcing the most appropriate printer and fitting the printer into around the electronics and the device enclosure.

The following case study explains how the FCL Components’ FCL-FTP-648 printer mechanism has been adapted by franchised distributor Inelco Hunter to be fully integrated into the final product.

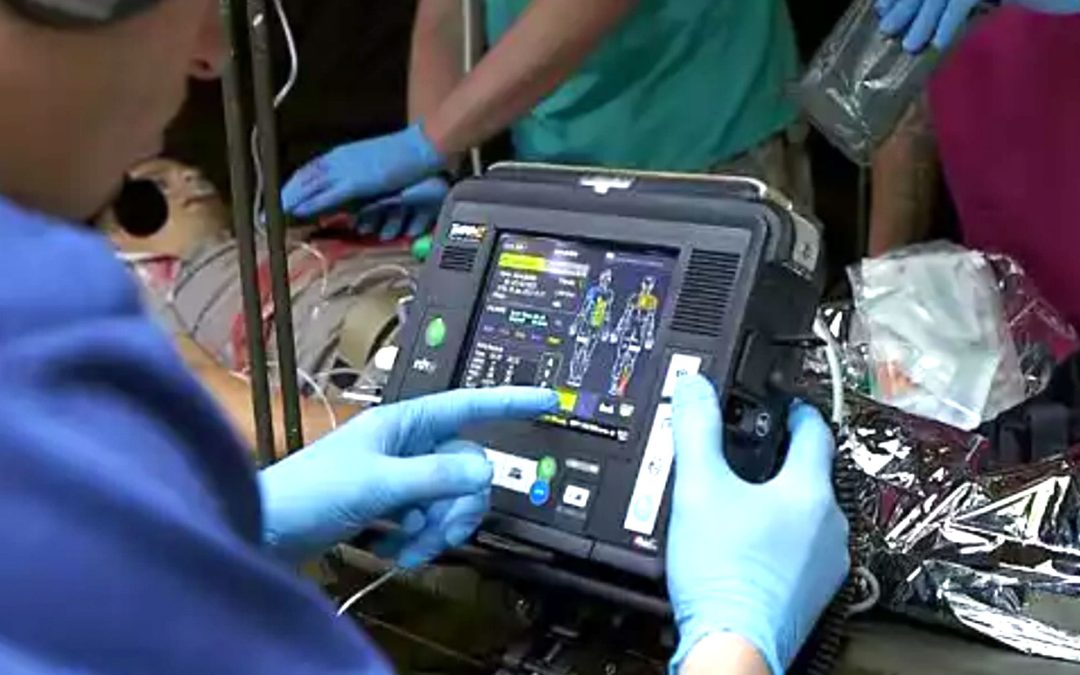

The End-product: Vital Signs Monitoring device

Inelco Hunter customer Philips specialises in the design, manufacture, sales, and worldwide distribution of remote monitoring and resuscitation solutions for pre-hospital and critical care services.

Philips is a trusted partner to customers on the frontline in time-critical situations – this includes large, complex and demanding military and government customers.

The Tempus Pro was developed as a new concept in vital signs monitoring. It places the needs of the pre-hospital care professional at the heart of its design. Ground-breaking in functionality, it is light enough to carry to the patient, small enough to hold in one hand and rugged enough to deploy in any situation.

The device, although small, is highly robust and packed with all the functionality needed. This includes ECG, defibrillation, laryngoscopy, and ultrasound combined with advanced patient data collection and sharing, real-time data streaming.

The Challenge

The Tempus Pro was developed for use in any environment, from ambulances, planes and boats to medical evacuation vehicles and battalion aid stations. Operating the device in such harsh, demanding environments set the standard for Inelco Hunter and FCL Components to match the concept with a ruggedised printing solution.

The solution had to reliably print ultrasound and ECG results in all types of environments, so weight, shock absorption, dimensions and power consumption were all very important factors.

The Solution

These crucial requirements were met by customising the FCL-FTP-648 printer mechanism. This 4-inch thermal printer features a metal body instead of the commonly used plastic body to provide several design advantages.

The dimensions of the printer with a metal frame are relatively small – a plastic body would require a larger structure to obtain the same rigidity. The metal frame provides robustness and guarantees a perfect alignment of the thermal head and platen, preventing the need for additional reinforcement.

The robust nature of the metal frame also optimises shock and vibration resistance, and functions as a heat sink for heat generated by the printing head, whilst shielding the components from any ESD generated by paper friction.

Conclusions

Inelco Hunter and FCL Components both have long-standing experience in the design and manufacture of high-quality printers and the Philips rugged printer mechanism solution met all of the stringent requirements of weight, shock absorption, dimensions and power consumption, where reliability and quality are both vital.

Inelco Hunter has been providing customised solutions for over thirty years and as the electronics industry continues to evolve, the role of distributors is shifting to strategic engineering partners. Inelco Hunter’s design-led distribution approach exemplifies this shift, offering companies a combination of technical expertise, high-quality components, and long-term support.

Inelco Hunter MD David Bushnell explains, “Our focus has always been to help our customers by being deeply involved in their engineering processes. By supporting our customers through each design decision, we help them avoid potential pitfalls, reduce time to market, and ultimately create more robust and competitive products.”