The potential applications for connectors in electronic and electrical applications has steadily evolved over the years, but the pace is increasing rapidly. The market for EV (Electric Vehicle) connectors is a good example. This article examines the requirements of some of the fastest-growing markets.

The evolution of the D-Style Connector

The D-Style connector interface was originally designed for the demanding avionics market. This robust connector interface has become the connector of choice for a wide variety of applications. Over the years, the expansion of potential markets has required enhanced technical requirements – for example, support for modern high-speed data transfer solutions like VHDCI.

Perhaps the most significant advance has been to incorporate multiple input streams into a single D-Style shell. High power, low power, video and RF, for example, can all be handled in a single shell, avoiding the need for multiple connectors.

Robotics – Communication and Control

From industrial automation to collaborative robots and autonomous drones, the capabilities of robotic systems have grown exponentially. Behind these impressive feats lie two crucial aspects: communication and control.

The most important feature to look for is precise data flow and coordination for uninterrupted operation. This is vital, as is the ability to withstand harsh conditions, vibrations, and electromagnetic interference. The world of robotics is very demanding. Typically, 10Gb data rates will be required to ensure seamless real-time communication and control.

Space-saving and low-weight attributes are other considerations, particularly in applications such as military drones. Connectors with a compact 10mm pitch will occupy a mere 25% of the size of traditional RJ45 connectors. This reduction in size not only allows for greater port density but also ensures secure mating, critical for stable communication in dynamic robotics environments.

ADAS – Driving into the Future

Although the race to produce self-driving cars is ongoing, Advanced Driver-Assistance Systems (ADAS) are already present in the automotive industry. High-speed networking and the downsizing of interconnectivity solutions has made this possible. Miniaturisation is key – for example, ADAS applications rely on miniaturised connector solutions for black-box applications.

The emergence of 5G technology is another factor – it provides significantly faster data transmission rates and lower latency than 4G LTE, enabling new possibilities for intelligent vehicles and Vehicle-to-Everything (V2X) communication.

PCB Card Edge Connectors

In an era where data speeds define technological progress, eliminating PCB Trace Loss is essential. The best approach is to select a connector that directly attaches to cables, bypassing traditional PCB routing. This eliminates the signal loss typically encountered on PCB traces, resulting in a significant improvement in Signal Integrity.

Backward compatibility is also essential. The mating interface needs to adhere to standard PCIe® AIC specifications, ensuring backward compatibility with Gen 4/3/2/1 systems.

Flex-to-Board Connectors

Flex-to-board connectors enable flexible and high-density interconnects between PCBs, LCDs, and various electronic components. In today’s data-driven world, secure high-speed data transmission is essential.

Flex-to-Board connectors can meet this challenge – capable of supporting high-speed gigabit data rates, state-of-the-art connectors are suitable for communication systems, data centres, and high-speed digital devices, for example.

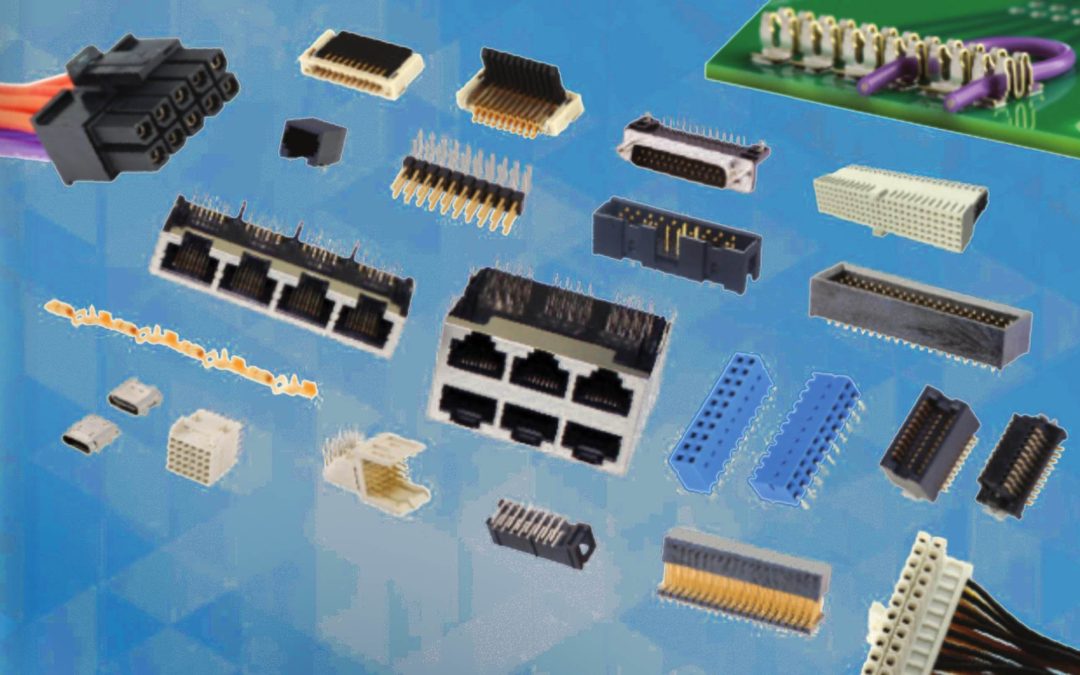

Choosing the Connector Product Range

There is a lot to be said for sourcing multiple connector types from a single source. Engineering support and technical advice can then be provided by a reliable, trusted supplier.

The Amphenol product range from Inelco Hunter is a good example of a global manufacturer offering a wide range of connector solutions that can support the demands of the fast-evolving connector markets.